Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

First blow away the garbage on the product surface with an air gun (manual) ------ polish and polish the product with defects (such as dents) (manual) ------ ha...

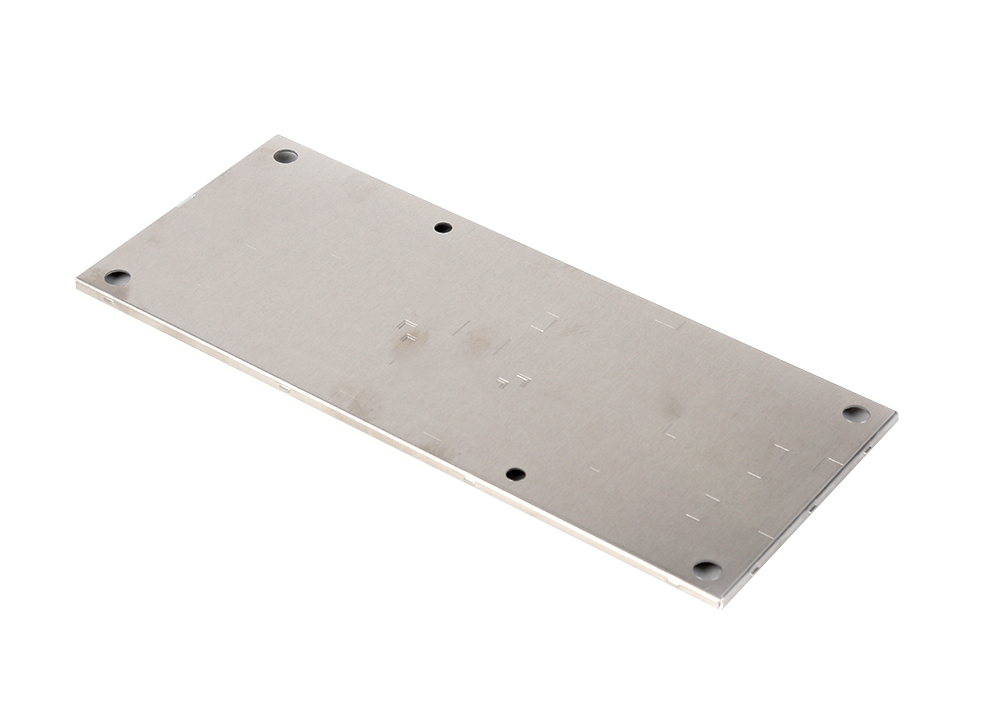

There are many kinds of metal die-casting processing. In addition, the specifications and sizes are different, some are simple, and some are complex. However, b...

Although the selection of materials for hardware parts processing is not very strict, it should not be sloppy. Good materials can not only ensure that the equip...

Precision parts processing became the industry standard at the end of the 1960s. Since then, various high-precision parts have been widely produced. Using CNC m...

There are many kinds of hardware parts processing. In addition, the specifications and sizes are different, some are simple, and some are complex. However, whet...

Hardware parts surface treatment is another common post-treatment process, and its surface treatment can be subdivided into: painting, electroplating, surface p...

Related News

Related News·How to divide the processing process of Shanghai CNC? ·How to develop the CNC part processing process ·What skills should CNC parts processing personnel possess? ·What are the advantages of CNC precision hardware processing ·Machining center control system ·Materials of Hardware Die Casting Mold ·CNC's functional function ·CNC CNC processing advantages ·Solve the way to solve the defect of zinc alloy pressure casting ·Workflow of high -speed drilling machine