Time:2022-11-15 Preview:

There are many kinds of metal die-casting processing. In addition, the specifications and sizes are different, some are simple, and some are complex. However, both complex and simple workpieces play an irreplaceable role in the application of various equipment. The die casting of five parts usually uses various raw materials to purchase, and then through different processing processes and steps to complete the formula workpiece.

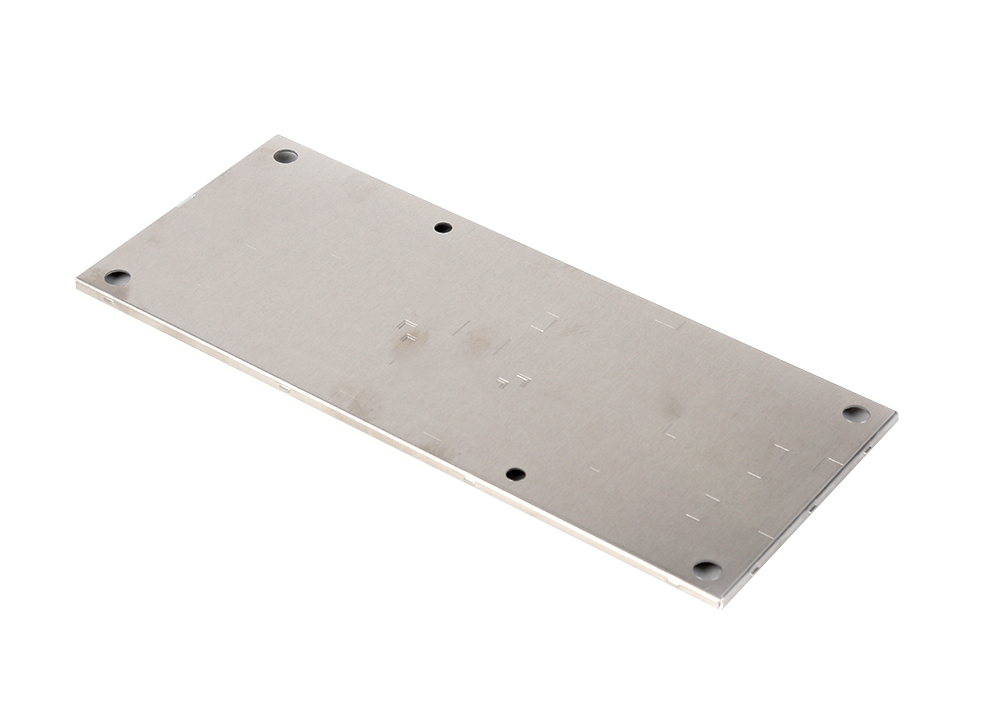

1. Sheet metal: the sheet metal mold is fast in production, low in cost and short in delivery time. Sheet metal has become a good substitute for the internal structural components of injection molded plastic, because it provides greater flexibility in the early stages of the design process.

2. NC machining: NC is an economic and effective solution to process complex shapes and strict zero tolerance parts. NC precision machining can process almost any shape

3. Turning: Turning process includes cutting, end face, thread, forming, drilling, knurling and boring. For the surface processing of hardware parts, turning is usually a good choice if you want to have a precise bearing surface on a complex machine.

Related News

Related News·Safety operating procedures for CNC processing ·CNC processing is a reduction in material production and manufacturing ·Important factors determining the spindle of CNC machine tools ·How to deal with the defects of aluminum alloy hardware die casting? ·Manipulating stamping hardware production and processing stamping parts caused by the way of turning ·What are the programming skills for CNC machining centers? ·CNC machining component surface processing method and factors to be considered ·When selecting the processing method, the following elements should be considered ·The most important parameter in CNC processing is God Horse ·Which company is good to find for CNC precision parts processing manufacturers?