Time:2022-11-22 Preview:

----Degreasing and degreasing ------ pickling ------ cleaning ------ phosphating ------ powder coating ------ baking (drying) ------ hanging down (manual) ------ checking the package (manual). There are thickness gauges and resistance tests to check the powder thickness.

1. Metal spraying and coating pretreatment: degreasing water washing pickling for 15-30min (hydrochloric acid and sulfuric acid) water washing neutralization water washing surface conditioning phosphating (skin friendly) for 15-30min

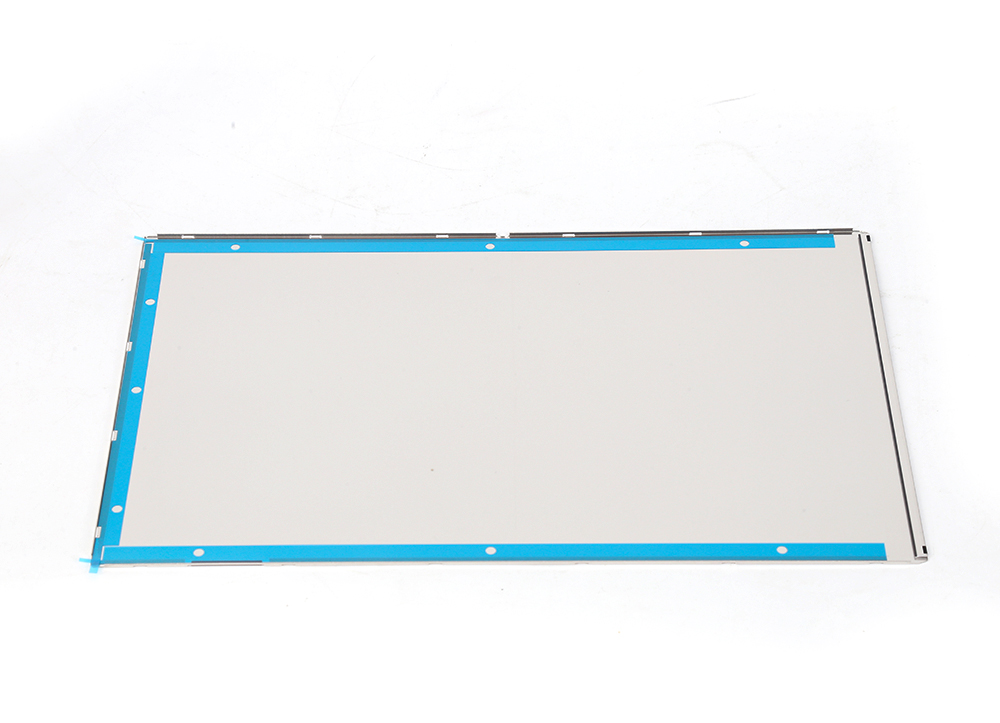

Hardware powder spraying requirements: the metal surface is free of rust, dark gray or even skin to the touch, the surface is free of white ash, and moisture is required for baking (pay special attention to no liquid flow marks at the water hole)

2. The first primer is mainly used for rust prevention. Before correction - DISK - after correction - leveling - baking time is generally determined according to the process time. The process temperature is generally set between 100 ° C and 120 ° C (the current temperature conditions are determined according to the process), and the best way is pipeline operation. Main equipment: DISK is available for spray gun

3. The third point is basically the same as the second point, but the workmanship is different. The temperature is between 120 and 180 degrees (depending on the characteristics and process of the paint), usually the top coat and gold oil.

4. The inspection specification of metal powder coating depends on the customer's requirements and the company's testing department. Main test method: drop ball test (use a solid ball with a diameter of 1.5CM and a hollow rod with a length of 1.5M to test the strength and adhesion of the paint). Baige experiment (art knife and tape used to test paint adhesion) is recorded as

5. Precautions: The surface shall be free of bumps, scratches, color differences, sags (flow marks), color stains, impurities, burrs, corrections, and leaks. The surface shall be leveled, free of bumps, and the surface of the base material shall be flat and smooth (must be polished before operation if necessary), as well as other requirements (packaging, etc.) specified by the customer

Related News

Related News·How to solve iron dumbs when the lathe is processed? ·Processing process flow of energy storage box ·Key points for operating CNC machining centers ·CNC Processing Center's craftsmanship and characteristics ·The advantages of stamping process in precision hardware processing ·CNC processing technology, although high -width ratio automation technology ·The advantages and work content of CNC ·When selecting the processing method, the following elements should be considered ·Effect of automatic stamping technology of hedging hardware processing ·How to choose the Longmen Processing Center (Longmen Milling Bed)?